Silica Sol Lost Wax Investment Casting

Key Process Facts

▶ Casting Tolerance According to ISO8062 DCTG 4-6

▶ Wide Range of Cast Ferrous Steel Selection According to EN、DIN、BS、AISI、ASTM、JIS standards

▶ Raw Casting Surface Roughness Ra 3.2-Ra6.3

▶ Minimum Wall Thickness 3-5mm

▶ Casting Process design based Casting Simulation and Workpiece Casting Optimization(Eg: Redesign your formerly Welded Part into an integral casting part)

▶ Unit Casting Weight between 5 grams and 60 kgs

▶ Maximum Casting Piece Size 600mm*600mm*500mm

▶ Complex lnner Contour realization by Ceramic Core,Water Solubale Core And Corresponding Compatible Tooling Design.

▶ The quality management of the Production Site is certified with ISO 9001:2015 and the production site possesses the certification of 2014/68/EU Directive for Pressure Vessels(Formerly known as the CE/PED)

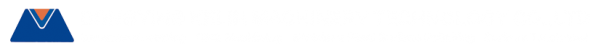

casting Simulation-Simulation of the progressive

Solidification of A Pump Housing

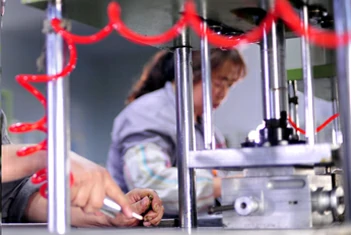

Investment Casting Production Site

Customer tooling Assets Management

Tooling Asset Management

Wax Injection

Semi-Automatic Wax Injection Machines For Small to Medium Sized Parts

Digitized Wax Injection Machine For Small Medium & Large Parts With Automatic Wax System

Wax Assembly

Finished Wax Parts Floor

Shell-Making Sand Coating

Shell-Making Drying

De-Waxing

Shell Firing

Pouring

Sprue Cutting

Reshaping

Reshaping